Spinning Processes and Material Impact

This training provides an in-depth understanding of fibers, fiber preparation, spinning technologies, mechanical recycling through fiber opening, quality control and sector challenges.

Operational Objectives

Understand economic, technical and environmental challenges of the yarn industry,

Understand fiber preparation and the three spinning processes (open-end, ring, air-jet),

Understand fiber opening processes for recycled short fibers,

Apply a product quality approach during spinning trials,

Become familiar with technical terminology.

Download program

-

Textile application engineers and technicians, new product development specialists.

-

Advanced.

-

Basic textile knowledge required.

-

Duration: 2 days (14 hours)

Format: Face-to-face

Location: CETI

-

The training combines structured theoretical input with hands-on practical workshops, including:

Digital media (PowerPoint presentations, videos, quizzes, etc.),

Presentation of raw material and product samples,

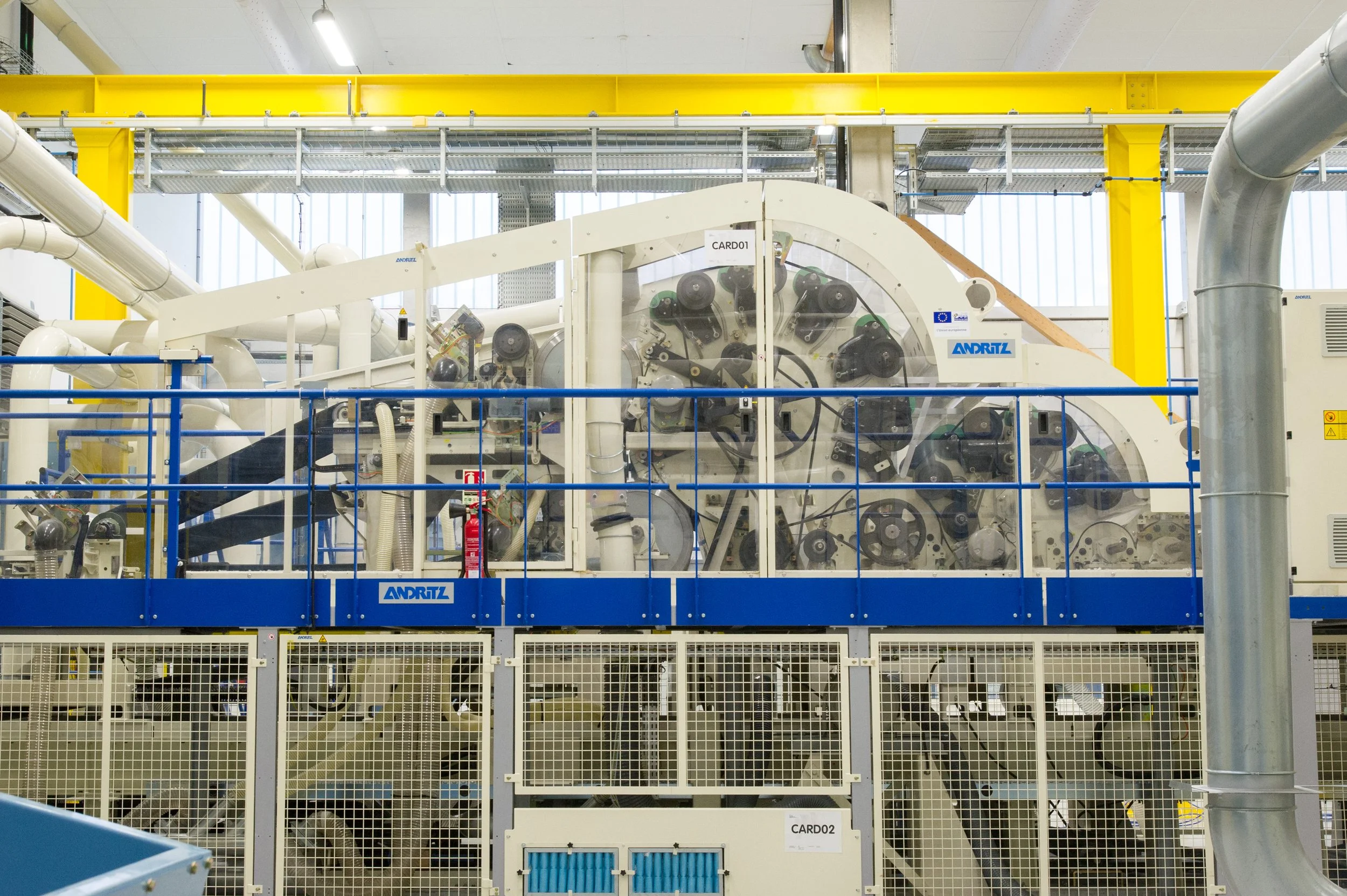

Illustration of textile processing technologies, as well as prototyping and characterisation trials on CETI’s technological platforms.

-

Assessment of learning outcomes through quizzes and technical discussions, complemented by a satisfaction questionnaire at the end of the training course.

-

Contact: contact@ceti.fr

Registration is confirmed after validation of training needs and subject to the number of participants.

-

The training course is open and accessible to people with disabilities.

Disability Officer: HR Manager

Email: rh@ceti.com

Phone: +33 (0)3 62 72 61 00

-

Training course delivered by a QUALIOPI-certified organisation for training activities.