Compounding & Spinning Processes

This training develops knowledge of thermoplastic resins for textile applications, material and product characterisation methods, compounding and polymer spinning processes, and filament transformation technologies.

Operational Objectives

Develop knowledge of the thermoplastic resin market,

Understand the fundamentals of controlled rheology,

Understand compounding and spinning technologies,

Identify innovation drivers in filament development,

Become familiar with technical terminology.

Download program

-

Textile application engineers and new product development specialists involved in synthetic fiber design and manufacturing processes.

-

Introductory (advanced level available on request).

-

No prior textile or thermoplastic polymer knowledge required.

-

Duration: 1 day (7 hours)

Format: Face-to-face (hybrid format available on request only)

Location: CETI

-

The training combines structured theoretical input with hands-on practical workshops, including:

Digital media (PowerPoint presentations, videos, quizzes, etc.),

Presentation of raw material and product samples,

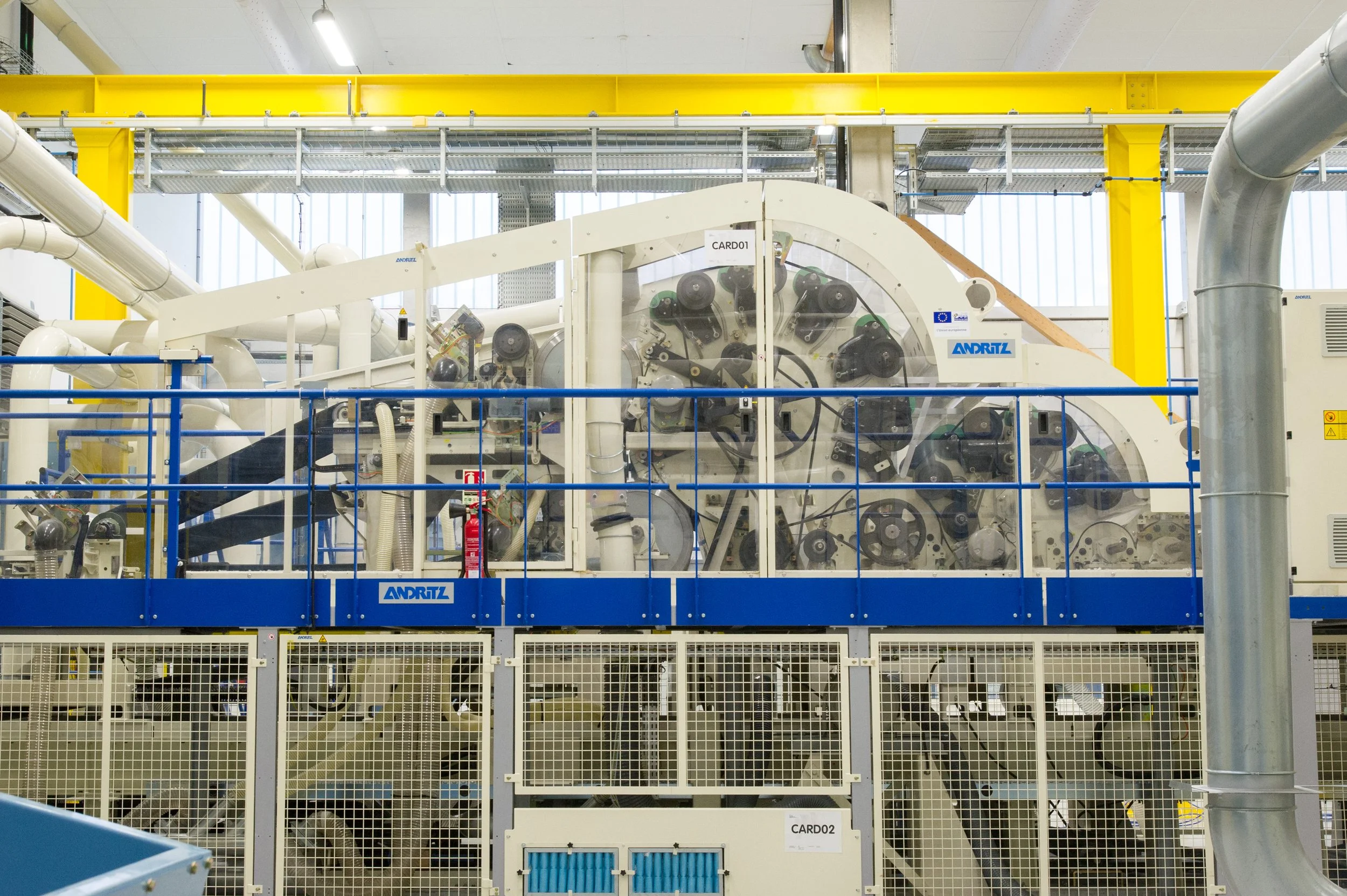

Illustration of textile processing technologies, as well as characterisation trials on CETI’s technological platforms.

-

Assessment of learning outcomes through quizzes and technical discussions, complemented by a satisfaction questionnaire at the end of the training course.

-

Contact: contact@ceti.fr

Registration is confirmed after validation of training needs and subject to the number of participants.

-

The training course is open and accessible to people with disabilities.

Disability Officer: HR Manager

Email: rh@ceti.com

Phone: +33 (0)3 62 72 61 00

-

Training course delivered by a QUALIOPI-certified organisation for training activities.