Spunbond Nonwowens Platform

CETI’s Spunbond Nonwovens platform provides industrial players with pilot and pre-industrial capabilities to develop, optimise and validate Spunbond nonwoven materials.

“The platform enables the production of continuous filament nonwovens directly from polymers, with a working width of 50 cm, offering high flexibility for material development and industrial validation.

Designed for applied R&D and pre-industrial validation, this platform supports the development of customised, high-performance Spunbond nonwovens under conditions representative of industrial constraints.”

Applications & industrial use cases

The Spunbond Nonwovens platform supports a wide range of industrial development and validation activities.

Development of mono-component and bi-component Spunbond nonwoven structures with controlled basis weight and filament diameter

Validation of polymer processability for Spunbond applications

Optimisation of mechanical, functional and surface properties of nonwovens

Development of customised or application-specific Spunbond products

Integration of recycled, functionalised or innovative polymers

Production of representative nonwovens for prototyping, testing and pre-industrial validation

How CETI uses this platform

CETI uses this platform to carry out technical developments and validation work on Spunbond nonwoven materials.

It enables feasibility studies, process optimisation and material qualification under industrially relevant conditions.

The platform is used to produce nonwoven samples for testing, prototyping and pre-industrial validation.

Activities are conducted by expert teams with strong know-how in polymers, nonwovens and textile processes.

The platform supports a wide range of technical services within CETI’s service offerings.

Looking to develop, validate or scale up a textile solution? CETI teams are available to discuss your project and identify the most relevant technical approach.

Consolidation & finishing capabilities

The Spunbond Nonwovens platform offers a wide range of web consolidation and finishing processes, enabling the development of nonwovens with tailored mechanical, functional and surface properties.

Consolidation processes:

Calendering

Hydroentanglement

Thermal bonding (oven)

Needle punching

Combined processes (needle-punched web followed by thermal bonding)

Finishing processes:

Smooth calendering

Kiss-roll coating

Padding

These processes can be combined to meet specific performance, durability or functional requirements.

Associated platforms

The Spunbond Nonwovens platform is fully integrated within CETI’s nonwovens technological ecosystem.

Nonwovens

->

Meltblown nonwovens

->

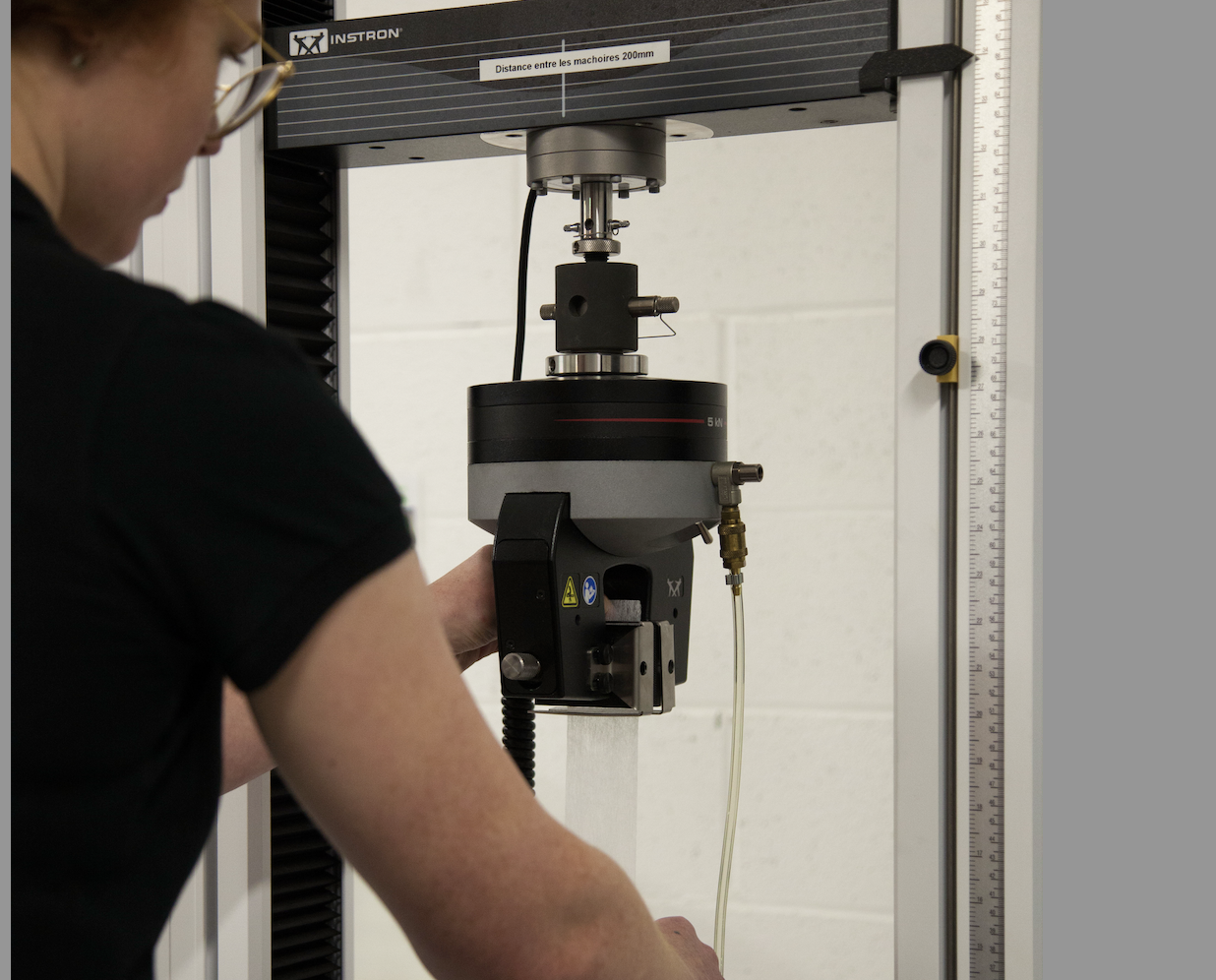

Characterization & Performance Measurement

->

Drylaid nonwovens

->

By combining the Spunbond Nonwovens platform with other nonwoven platforms, CETI offers more than 150 possible combinations of web forming and consolidating processes.

This integration enables CETI to develop highly customised nonwoven solutions tailored to industrial and application-specific requirements.

Links to expertise & services

This platform supports several areas of CETI expertise, including nonwovens engineering, polymer processing, fiber development and technical textiles.

-

-

Synthetic & natural fibers

-

Textile innovation

-

-

Recycling & Eco-design

The Spunbond Nonwovens platform is mobilised across CETI’s service offerings.

Our services

Research and development / Engineering / consulting

Technology and market monitoring, innovation design, design thinking, modeling, specification control, eco-design.

Prototyping /

pre-production / INDUSTRIAL TRANSFER

Custom-built, optimal value chain solutions for your projects. Circular textile creativity, tailored to each sector and each process.